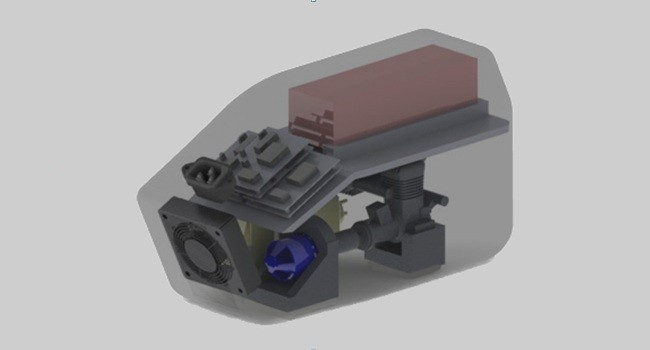

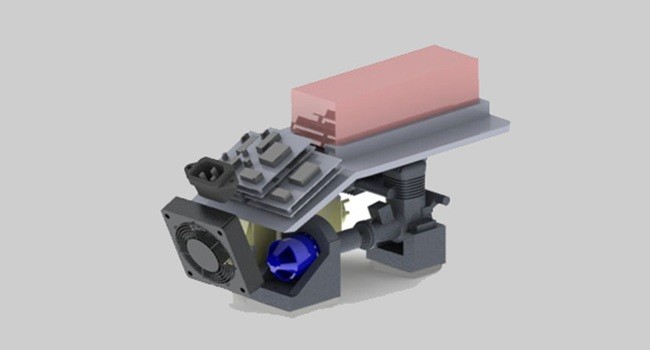

PORTABLE MICRO POWER UNIT

Small-scale electronic devices such as computers, GPS receivers, and mobile phones are an integral part of day to day life in a technologically advanced society such as ours. These devices require compact energy supplies, a demand most typically fulfilled today by rechargeable batteries. However, there are many problems with batteries. They have a limited energy density, and their disposal is harmful to the environment - to name a few. Given the benefits of the cube-square law, which states that a scaled down device’s surface area will be proportional to the square root of the scale factor, and the mass to the cube root, as well as the benefits of higher strength-to-density materials like silicon, the power density of a micro engine could exceed that of a conventional large-scale engine, resulting in a desirable alternative to and replacement for batteries.

Conventional battery-based portable power supplies have difficulty satisfying the requirements for high-tech devices. They need frequent recharging, and increase substantially in size as more energy is required. Micro power generation via the combustion of hydrocarbons and similar fuels is considered to be a compatible alternative due to the advantages of portability, higher energy density, longer operating time and easier/faster refueling innate with this type of engine. In order to design a micro system that provides stable power output in a mechanically/thermally safe manor, advanced multi-physics CAE analysis correlated with experimental investigation is a must. SDM has broad experience in mechatronic system design, and in the development of novel technologies – which are a perfect fit for our micro engine project.